As a social media specialist with Wilcox, one of my primary objectives is to share company news and information with the world via Twitter, Facebook, and LinkedIn. From my first day with Wilcox, I expressed great interest in field activities; I wanted to see first-hand what we do.

On October 4, 2012, I had the opportunity to ride along with Curtis Taylor, one of our Industrial Services Project Managers, to a stack testing event taking place in western Indiana. The event was supposed to have taken place the day before, but had been postponed due to rain. I would come to find that weather is huge factor in stack testing, not only in regards to safety, but how much the moisture in the product effects the emissions in the stack. Any number of weather elements like temperature, barometric pressure and wind velocity need to be factored into stack testing.

I brought a camera along with my PPE—a hard hat, safety glasses and high visibility vest, and donned my Army surplus boots. We were going to a working quarry, so with all those big trucks milling around, I wanted to be seen and safe during my visit.

This particular stack testing event was a three-person operation: one technician was in the lift with the sampling train, a second technician was on the ground observing the Dry Gas Meter (DGM) and signaling when the technician on the lift can perform the next leg of the test. In the meantime, a third technician observed the opacity of the smoke coming out of the stack, also known as a Visible Emissions Test.

Upon arrival, one of our seasoned field technicians was already performing the initial testing on the client’s chimney-like structure (called a stack) with what we call a sampling train—in this instance, we were using a PM train as we were performing PM/PM10 testing. PM stands for “particulate matter,” which is measurable in the air we breathe. Too much particulate matter in the air is dangerous because it can be captured in our lungs and kept there, resulting in illness (and can often become fatal). The PM10 test separates the particulate depending on the size of the particles. PM10 is particulate matter that is less than 10 microns in size. How small is that? Think of a cross-section of a strand of human hair—that is about 10 microns.

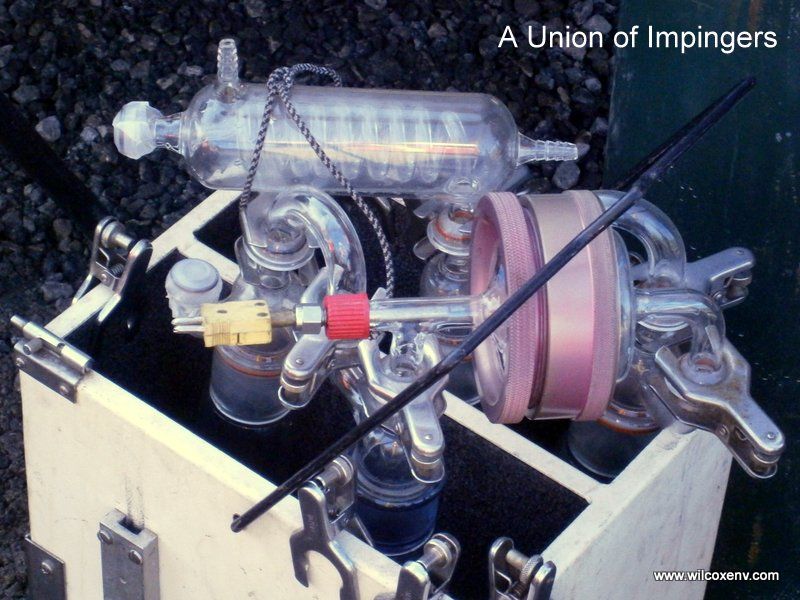

From far away, the PM train looks like an oversized metal detector, without the rounded end, and its primary function is to collect the gas coming up through the stack. Upon closer inspection, I was able to get a good look at the instrument. The phalange-like tubes are called probes; some of the probes collect gas emitted from the stack, running it through several filters and impingers (glass tubes) in order to be analyzed later. The other probes collect real-time data as displayed on a DGM. This data is then collected in a spreadsheet by the second technician, and is then used to calculate the emissions of the stack.

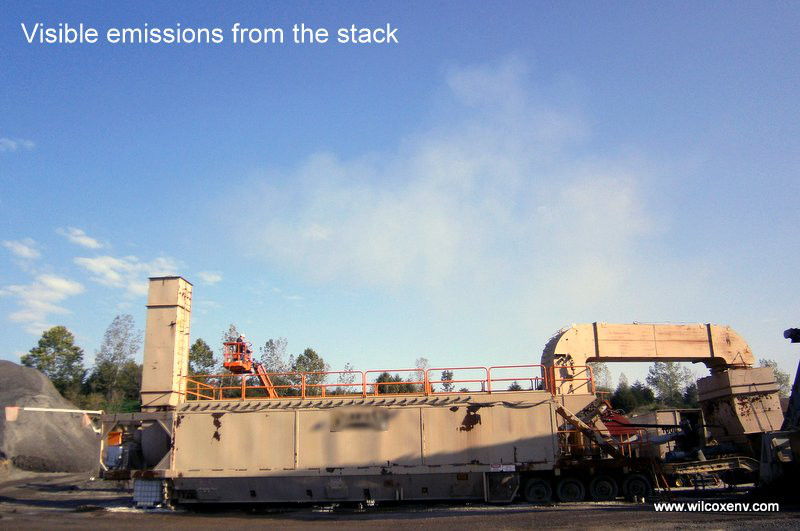

So why was all this happening? The client’s equipment in the quarry was a Drum Mix Asphalt Plant (a structure set up drive-thru style in order to quickly deposit aggregate into a dump truck). Attached to this facility is a baghouse, and attached to the baghouse is the stack. Wilcox was hired to perform compliance testing of this facility’s stack in order for the client to obtain a permit from IDEM.

In order to protect the health and welfare of the surrounding communities, IDEM is required to regulate this asphalt plant to control its emissions. The permit is a permission slip, per se, to ensure that the plant is in compliance with the law.

It would seem that with any form of environmental testing, issues can arise. Our team discovered the stack was not producing optimal flow, and was therefore unable to give a clear reading right away. An ideal flow would be laminar, which means the air flows in parallel layers, with no disruption between the layers, straight out of the stack.

I am quite certain that most people would be as surprised as I was to learn that stack testing is a lot more involved than inserting a probe into a stack. It takes a dedicated and focused team effort along with high regard for safety and awareness of the surrounding environment. Stack testing also requires acuity for mathematics and problem-solving in general. Our Air Analysis team possesses these skills and I feel honored to have experienced it up close.